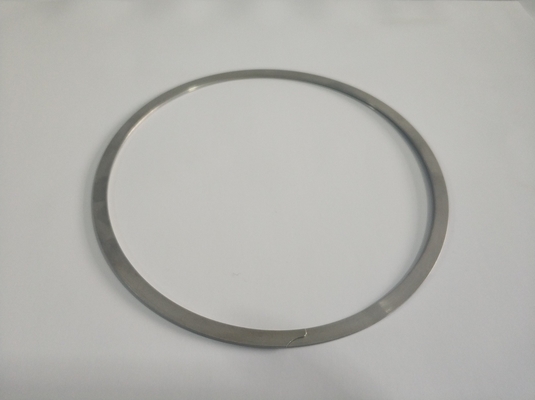

Precision Spiral Stainless Steel Tension Springs

Surface Finish

1, Coating :nickel , zinc,chrome,Dacromet,teflon,silver ,gold etc.

2, Anodized : any color , can according the Panton card .

3, Sand blast,Powder coating

4, Painting

5, Laser marking,printing .

Specification:

1. Item name: Customized High Tension Coil Springs

2. Material Sections: Round wire/Flat wire

3. Wire diameter: 0.15~50mm, according to specific requirement

4. Material: Carbon steel 1066/ 65/ 65MN 9260/ SUP6,SUP7/ 60SiCr7/ 60C2/ 60Si2Mn

Stainless steel304/S30400/SUS304/X5CrNi18-10/0Cr18Ni9/ 316/ S31600/SUS316/X5CrNi17.12.2/0Cr17Ni12Mo2 / 631/ S17700/ SUS631/ 1.4568/ 17-7PH

Nickel alloy/Nimonic alloy Inconel X-750/ NO7750/ 2.4669/ GH4145 / Inconel 718/ NO7718/ 2.4668/ GH4169

5. Processing craft: Material purchased—Material testing—production—heat treatment

—surface treatment—final testing—package—shipping

6. Heat treatment: Tempering,Stress relieving

Galvanised,Chrome plated,Nickel plated,Phosphated

7. Quality Standard:ISO 9001:2008, TS 16949 and ISO 14001

| Part Number |

Housing Diameter(in) |

Load

(lb)

|

Work Height(in) |

Max.Free Height(in) |

Number of Waves |

Thickness

(in)

|

Radial Wall(in) |

Crimp |

Groove Diameter

(in)

|

Groove Width

(in)

|

| WHW-75 |

0.75 |

25 |

0.08 |

0.114 |

3 |

0.035 |

0.065 |

N |

0.796 |

0.119 |

| WHW-87 |

0.875 |

30 |

0.085 |

0.11 |

3 |

0.042 |

0.085 |

N |

0.931 |

0.115 |

| WHW-100 |

1 |

34 |

0.085 |

0.12 |

3 |

0.042 |

0.085 |

N |

1.066 |

0.125 |

| WHW-112 |

1.125 |

38 |

0.1 |

0.125 |

3 |

0.05 |

0.128 |

N |

1.197 |

0.13 |

| WHW-125 |

1.25 |

40 |

0.1 |

0.135 |

3 |

0.05 |

0.128 |

N |

1.33 |

0.14 |

| WHW-137 |

1.375 |

45 |

0.1 |

0.125 |

4 |

0.05 |

0.128 |

N |

1.461 |

0.13 |

| WHW-150 |

1.5 |

50 |

0.1 |

0.135 |

4 |

0.05 |

0.128 |

N |

1.594 |

0.14 |

| WHW-162 |

1.625 |

55 |

0.11 |

0.135 |

4 |

0.062 |

0.158 |

N |

1.725 |

0.14 |

| WHW-175 |

1.75 |

60 |

0.11 |

0.14 |

4 |

0.062 |

0.158 |

N |

1.858 |

0.145 |

| WHW-187 |

1.875 |

63 |

0.11 |

0.141 |

4 |

0.062 |

0.158 |

N |

1.989 |

0.146 |

| WHW-200 |

2 |

65 |

0.11 |

0.15 |

4 |

0.062 |

0.158 |

N |

2.122 |

0.155 |

| WHW-212 |

2.125 |

70 |

0.13 |

0.17 |

4 |

0.078 |

0.188 |

N |

2.251 |

0.175 |

| WHW-225 |

2.25 |

75 |

0.13 |

0.175 |

4 |

0.078 |

0.188 |

N |

2.382 |

0.18 |

| WHW-237 |

2.375 |

80 |

0.13 |

0.18 |

4 |

0.078 |

0.188 |

N |

2.517 |

0.185 |

| WHW-250 |

2.5 |

84 |

0.13 |

0.183 |

4 |

0.078 |

0.188 |

N |

2.648 |

0.188 |

| WHW-262 |

2.625 |

88 |

0.17 |

0.22 |

4 |

0.093 |

0.225 |

N |

2.781 |

0.225 |

| WHW-275 |

2.75 |

94 |

0.17 |

0.229 |

4 |

0.093 |

0.225 |

N |

2.914 |

0.234 |

| WHW-287 |

2.875 |

97 |

0.17 |

0.225 |

4 |

0.093 |

0.225 |

N |

3.051 |

0.23 |

| WHW-300 |

3 |

100 |

0.17 |

0.23 |

4 |

0.093 |

0.225 |

N |

3.182 |

0.235 |

| WHW-312 |

3.125 |

103 |

0.185 |

0.25 |

4 |

0.111 |

0.281 |

Y |

3.315 |

0.255 |

| WHW-325 |

3.25 |

106 |

0.185 |

0.25 |

4 |

0.111 |

0.281 |

Y |

3.446 |

0.255 |

| WHW-350 |

3.5 |

115 |

0.185 |

0.245 |

4 |

0.111 |

0.281 |

Y |

3.71 |

0.25 |

| WHW-362 |

3.625 |

117 |

0.185 |

0.25 |

4 |

0.111 |

0.281 |

Y |

3.841 |

0.25 |

| WHW-375 |

3.75 |

121 |

0.185 |

0.255 |

4 |

0.111 |

0.312 |

Y |

3.974 |

0.26 |

| WHW-387 |

3.875 |

126 |

0.185 |

0.26 |

4 |

0.111 |

0.312 |

Y |

4.107 |

0.265 |

| WHW-400 |

4 |

130 |

0.185 |

0.255 |

4 |

0.111 |

0.312 |

Y |

4.24 |

0.26 |

| WHW-412 |

4.125 |

134 |

0.185 |

0.258 |

4 |

0.111 |

0.312 |

Y |

4.365 |

0.263 |

| WHW-425 |

4.25 |

140 |

0.185 |

0.264 |

4 |

0.111 |

0.312 |

Y |

4.49 |

0.269 |

| WHW-450 |

4.5 |

150 |

0.185 |

0.25 |

5 |

0.111 |

0.312 |

Y |

4.74 |

0.255 |

| WHW-475 |

4.75 |

160 |

0.185 |

0.252 |

5 |

0.111 |

0.312 |

Y |

4.995 |

0.257 |

| WHW-500 |

5 |

170 |

0.185 |

0.247 |

5 |

0.111 |

0.312 |

Y |

5.26 |

0.252 |

Why Choose Us?

♦Industrial experience

We specialized in the spring field since the year of 1993.

♦Sample availability

We can send samples for your approval within 7 days;Free of charge if we have available tool.

♦Quickly Delivery

As usual within 10 days.

♦Good service and best quality

Our business belief is "best competitive price,good service and best quality"

QC Profile

For over 20 years Lisheng has been committed to quality and customer satisfaction. In accordance with the requirements of ISO 9001:2008, TS 16949 and ISO 14001, we have established and are continuously improving upon our quality management systems.

Lisheng 's history of quality and strict compliance with military and aerospace standards has earned Lisheng an approved supplier status with many leading OEM manufacturers worldwide. We are dedicated to providing superior products with exceptional value.

Lisheng takes pride in providing the highest level of quality at every stage of the ordering and manufacturing process, from design to delivery. If you should have any comments, compliments or complaints, we want to know. Please let us know how we are doing by e-mailing: sales@lispring.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!